China is a large country in the TCM industry, with a market capacity of one trillion yuan. At the same time, we are also a large country in the production of TCM equipment, but some of the enterprises are still in the industrial 2.0 stage. The State proposed in the 14th Five-Year Plan and the 2035 Visionary Goals: "Promote high-end, intelligent and green traditional industries". China's TCM production ranks among the world in terms of the enterprise number, product varieties, specifications and output. Under the influence of market and policy factors, the transformation and upgrading of the TCM industry is imminent. However, in the context of today's situation, there are interruptions between manufacturing processes in TCM companies, such as preparation and infusion, repeated sterilization, shaped carriers, manual-based material flow, lack of interoperability and interconnection between equipment, and the prevalence of information silos, all of which make industrial upgrading a more complex challenge. Tuskrobots has proposed a solution for this scenario with high cleanliness, high space utilization and spatial information interconnection, which can better adapt to the above problems.

Tuskrobots cooperates with a well-known domestic high-tech enterprise group in the bio-pharmaceutical industry.

Disinfection room solutions

In view of its high cleanliness requirements, repeated disinfection is required for personnel entry and exit. Multiple door controls lead to extremely low manual handling efficiency, and pharmaceutical handling has strict requirements for batch time, etc. Tuskrobots has developed a complete disinfection room solution for this purpose. With the wireless control module provided, the link between the automatic door and the disinfection equipment is directly opened and the entire process of the door opening and entering, the disinfection equipment opening, timing, stopping and opening and closing mutually exclusion is completed fully automatically. With intelligent time control and automatic batch number audit for autonomous transmission, the operation is significantly improved in terms of timeliness and efficiency, reducing contamination and ensuring high GMP requirements.

One button for the whole process

In response to the strict spatial segregation of the processes in this project, Tuskrobots has equipped each process with a terminal operating screen. Workers can call for materials and transport them for temporary storage with a single keystroke, while at the same time entering information about the materials and querying, locking and modifying the status of the stock position. The robot can automatically complete the whole process of material storage, cooling timing and storage transferring for the cooling process of TCM preparation production. It ensures the timeliness and accuracy of the transfer of semi-finished products in each process, reducing material losses, improving the utilization of resources and reducing management costs.

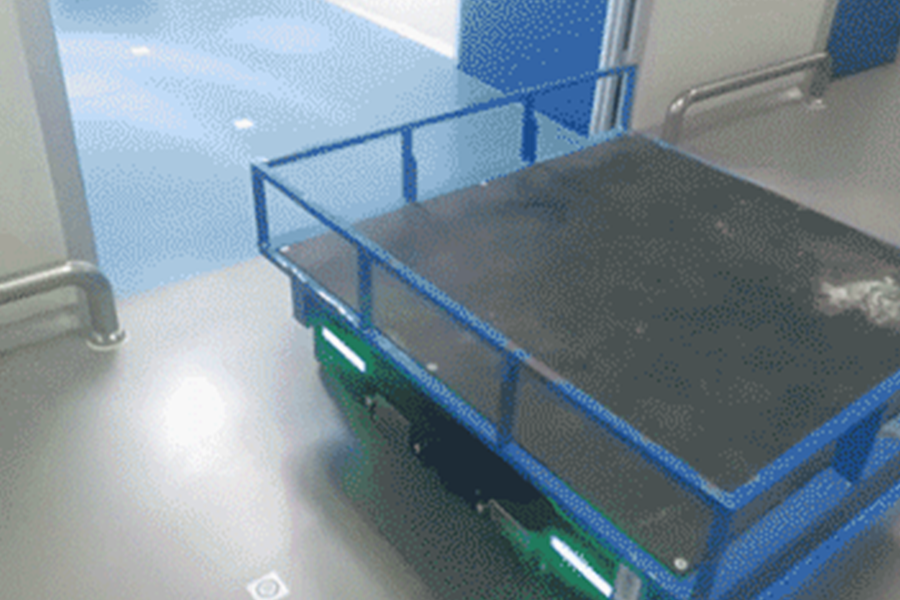

Shaped carriers

The diversity of products in the pharmaceutical industry means that there are many different forms of carriers. For this project, Tuskrobots developed a shaped pallet recognition algorithm that can identify and adjust pallets of different shapes. It is a perfect replacement for the manual floor cattle, which provides a great convenience for the automation transformation of the company.

Tuskrobots has spared no effort in penetrating the pharmaceutical manufacturing industry and has implemented several successful cases in pharmaceutical production plants. The pharmaceutical industry is complex, diverse, demanding and unique. Therefore, we are always on the path of learning from experts and partners in the industry, striving to make a contribution to the intelligent manufacturing of pharmaceuticals in China.