Provide you with the latest Industry knowledge about Automotive Electronics Industry Pallet Handling Robot.

What is Automotive Electronics Industry Pallet Handling Robot

The Automotive Electronics Industry Pallet Handling Robot is a type of robot used in the automotive industry to handle and transport pallets containing electronic components and parts used in the manufacturing process of automobiles.

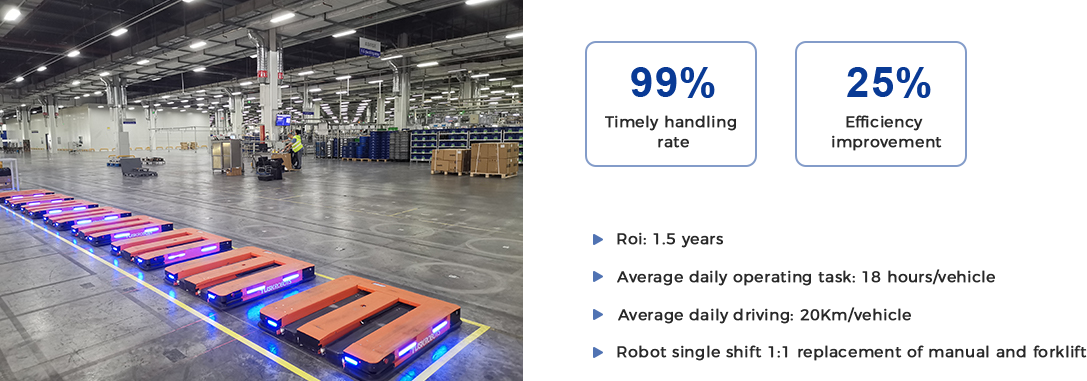

These robots are designed to move pallets from one location to another within a factory or warehouse setting, often working alongside human workers or other automated machinery. They can lift and move heavy pallets with precision and speed, improving efficiency and reducing the risk of injury to human workers.

Pallet handling robots are typically equipped with sensors and programming that allow them to navigate around obstacles and avoid collisions with other equipment or workers. They can also be programmed to work in a variety of different environments and to perform specific tasks, such as loading and unloading pallets from trucks or stacking pallets in storage areas.

Overall, pallet handling robots play an important role in the automotive electronics industry by increasing productivity, reducing costs, and improving safety in the workplace.

The Benefits of Pallet Handling Robots in Automotive Electronics

The use of pallet handling robots in the automotive electronics industry has become increasingly popular in recent years, and for good reason. These robots offer numerous benefits that can help manufacturers improve efficiency, productivity, and safety in the workplace. Here are some of the key benefits of pallet handling robots in automotive electronics:

1. Increased productivity: Pallet handling robots can work around the clock without the need for breaks or rest periods, resulting in increased production output. They can also perform tasks quickly and accurately, reducing the time it takes to move pallets and components around the factory floor.

2. Improved efficiency: Pallet handling robots can be programmed to work in a specific sequence or pattern, reducing the likelihood of errors or delays in the manufacturing process. They can also work alongside human workers, allowing for a more efficient and streamlined workflow.

3. Enhanced safety: Pallet handling robots can perform heavy lifting and moving tasks, reducing the risk of injury to human workers. They can also be programmed to avoid collisions with other equipment or workers, making the workplace safer for everyone.

4. Cost savings: The use of pallet handling robots can help manufacturers save money in the long run by reducing labor costs and minimizing the risk of product damage or loss during handling and transport.

5. Flexibility: Pallet handling robots can be programmed to work in a variety of different environments and to perform specific tasks, making them highly adaptable to different manufacturing settings and requirements.

Overall, the benefits of pallet handling robots in the automotive electronics industry are clear. They offer increased productivity, efficiency, and safety, while also reducing costs and providing flexibility in the manufacturing process. As the automotive industry continues to evolve and adapt to new technologies, pallet handling robots will likely play an increasingly important role in improving manufacturing processes and driving innovation.

Maximizing Productivity with Automotive Electronics Industry Pallet Handling Robots

In today's highly competitive manufacturing landscape, maximizing productivity is a top priority for businesses in the automotive electronics industry. One way to achieve this goal is by implementing pallet handling robots in the production process. Here are some ways in which these robots can help manufacturers maximize productivity:

1. Streamlined processes: Pallet handling robots can move pallets containing electronic components and parts with speed and precision, reducing the time it takes to move them from one location to another. This helps to streamline the manufacturing process and increase overall productivity.

2. Improved accuracy: Pallet handling robots are highly accurate and can perform repetitive tasks with consistent precision. This reduces the likelihood of errors and the need for rework, which can help to speed up the production process and increase productivity.

3. 24/7 operation: Unlike human workers, pallet handling robots can work around the clock without the need for breaks or rest periods. This means that production can continue even outside of regular working hours, further increasing productivity.

4. Enhanced safety: Pallet handling robots can perform heavy lifting and moving tasks, reducing the risk of injury to human workers. This helps to ensure that the production process continues smoothly without any delays due to workplace accidents or injuries.

5. Cost savings: The use of pallet handling robots can help to reduce labor costs and minimize the risk of product damage or loss during handling and transport. This leads to cost savings for manufacturers and helps to maximize overall productivity.

By implementing pallet handling robots in the automotive electronics industry, manufacturers can maximize productivity, streamline processes, and improve safety while also reducing costs. As the manufacturing landscape continues to evolve, pallet handling robots will likely play an increasingly important role in helping businesses stay competitive and productive.